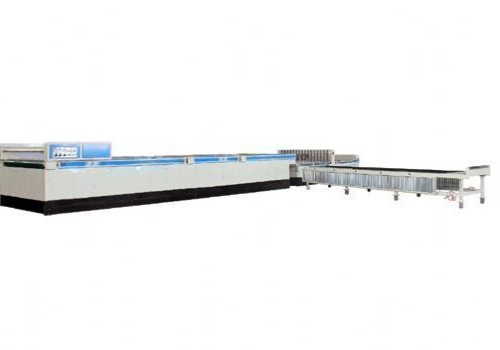

Product: Right-angle stacker

Model No.: SD20B

Applicable Paper Width: 1200-2300mm

Configuration:

l The maximum paper collecting length: 3.5 m;

l The maximum paper stacking height: 250 mm;

l The minimum occupying length of the machine is about 13 m;

l The conveyance device is divided into three sections; the first section is equipped with a strip pressing mechanism which makes the input cardboards be stacked in order. There is a paper ejecting rod between the first and second conveyor belts. The rod and the belts cooperate with each other and, under the control of an electrical system, synchronize the cooperation of different speeds in all sections and, if appropriate, lift the paper ejecting rod, so as to carry out accurate separation of cardboards by order/lot. Each section is driven by an AC frequency conversion motor, runs synchronously with the production line, and generates proper paper stacking ratio in conveyance according to paper length so that the paper sheets are stacked in order;

l There is a retractable front paper blocking plate installed at the end of the conveyance section to tidy the cardboards stacked on the hung rail;

l Right-angle lateral movement device is composed of feed-out roller assembly, rear paper blocking plate assembly and hung rail assembly, etc. The lifting of the hung rail assembly is driven by a brake motor and there are counterweights at both ends of the hung rail assembly; therefore, the mechanical impact to the whole machine caused by lifting of paper stacking platform is better reduced and the operation is much more stable;

l The feed-out rollers are arranged closely in the feed-out roller assembly and the rotating speed of the feed-out rollers is changed automatically according to the operation state. When the cardboards on the hung rail assembly fall onto the feed-out roller assembly, the rear paper blocking plate assembly is driven by the motor to move backward a set distance and the feed-out rollers speed up the stable and rapid output of cardboards.

Paper Width (mm) | External Dimensions L×W×H (mm) | Weight (T) | Total Power of Motor (kW) |

1,400 | 12,600×1,800×1,050 | 5 | 14 |

1,600 | 12,600×2,000×1,050 | 5.5 | 14 |

1,800 | 12,600×2,200×1,050 | 6 | 17 |

2,000 | 12,600×2,400×1,050 | 6.5 | 17 |

2,200 | 12,600×2,600×1,050 | 7.5 | 17 |

2,300 | 12,600×2,700×1,050 | 8 | 17 |